SBC valve guides are critical components that support the valve during engine operation, ensuring proper alignment and heat transfer. They play a vital role in maintaining engine performance and longevity by guiding the valve stem and preventing misalignment, which can lead to increased oil consumption and reduced efficiency.

Overview of SBC Valve Guides

SBC valve guides are essential components designed to support the valve stem during engine operation, ensuring proper alignment and preventing misalignment. They play a crucial role in maintaining engine performance by guiding the valve stem and transferring heat for cooling. When valve guides become worn, they can lead to increased oil consumption and reduced engine efficiency. SBC valve guides are available in various sizes, such as 1.94, 2.02, 1.50, and 1.60, catering to different engine specifications. These guides are often crafted from durable materials like Manganese Bronze, known for their strength and heat-transfer properties. Properly installed valve guides ensure stable valve train operation, prevent excessive wear, and maintain optimal engine performance. They are a critical part of the valve train system, contributing to the overall longevity and reliability of the engine. Regular inspection and maintenance of SBC valve guides are vital to prevent issues like oil leakage and valve misalignment.

Historical Background and Development

The development of SBC valve guides traces back to the early days of internal combustion engines, where the need for precise valve operation became critical. Initially, valve guides were cast directly into engine heads, but this method often led to wear and misalignment issues. Over time, removable valve guides were introduced, offering better durability and easier maintenance. The Small Block Chevrolet (SBC) engine, known for its reliability and performance, popularized the use of high-quality valve guides. Manufacturers began experimenting with materials like Manganese Bronze, which provided superior strength and heat-transfer properties. Modern SBC valve guides are precision-engineered using CNC turning centers, ensuring tight tolerances and optimal performance. This evolution reflects advancements in engine technology, emphasizing the importance of valve guide durability and precision in maintaining engine efficiency and longevity.

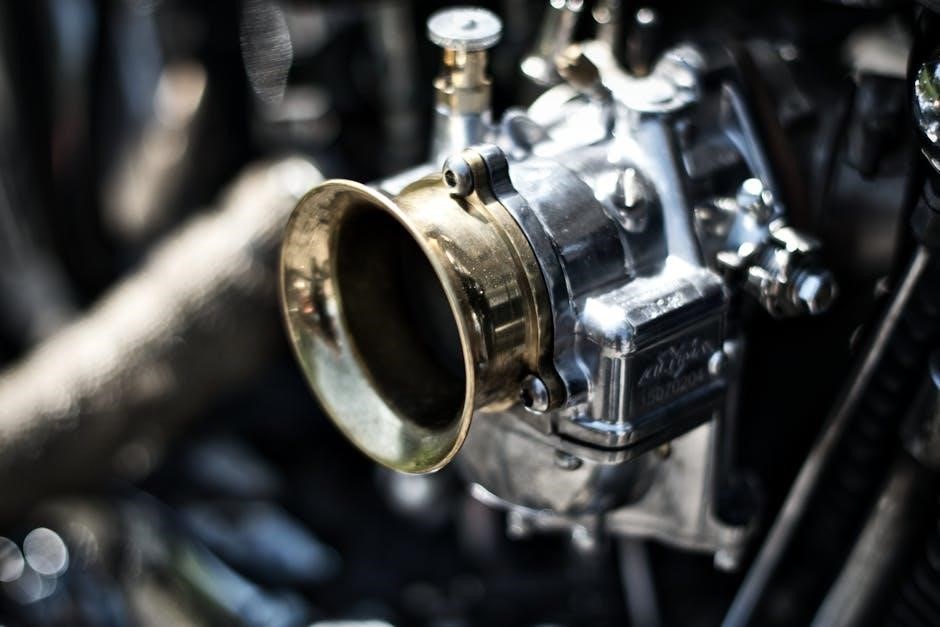

Design and Construction of SBC Valve Guides

SBC valve guides are precision-engineered to ensure durability and optimal performance. Their design features a cylindrical structure that supports the valve stem, with tight tolerances for proper alignment and minimal wear.

Key Components of SBC Valve Guides

The key components of SBC valve guides include the guide body, inner diameter, and outer diameter. The guide body is the main structural part, typically made from durable materials like Manganese Bronze or proprietary blends for strength and heat resistance. The inner diameter is precision-machined to fit the valve stem snugly, ensuring smooth operation and minimizing wear. The outer diameter is designed to fit securely into the cylinder head, maintaining proper alignment and preventing movement. Some guides also feature hardened surfaces or coatings to enhance durability and reduce friction. Additionally, certain designs incorporate lubrication pathways to ensure consistent oil flow, which is critical for maintaining temperature control and reducing wear over time. These components work together to provide stability, support, and efficient operation of the valve train system.

Types of SBC Valve Guides

SBC valve guides are available in various types to cater to different engine requirements and performance needs. The most common types include original equipment (OE) guides, which are designed to match factory specifications, and performance guides, made from upgraded materials for enhanced durability. High-performance guides often feature advanced materials like Manganese Bronze or proprietary blends, offering superior strength and heat resistance. Some manufacturers also offer hardened or coated guides to reduce wear and friction. Additionally, there are specialized guides designed for specific applications, such as oversized or undersized guides for engine rebuilding or high-lift camshaft setups. Each type is tailored to provide optimal performance, stability, and longevity for the valve train system, ensuring proper alignment and minimal oil consumption. The choice of guide type depends on the engine’s intended use, whether for daily driving, racing, or heavy-duty applications.

Manufacturing Processes and Materials

The manufacturing of SBC valve guides involves precise processes to ensure durability and performance. High-quality materials are selected to withstand the harsh engine environment. Manganese Bronze is a common choice due to its strength, wear resistance, and excellent heat transfer properties. Some manufacturers use proprietary blends that combine bronze with other alloys for enhanced performance. The guides are typically produced using CNC turning and machining to maintain tight tolerances and ensure a perfect fit. Additional processes like heat treatment and surface finishing are applied to improve hardness and reduce friction. Advanced manufacturing techniques, such as precision grinding and honing, ensure the guides meet strict specifications. The combination of superior materials and meticulous manufacturing processes results in valve guides that provide long-term reliability, minimal wear, and optimal engine performance. These processes are critical to maintaining the integrity and functionality of the valve train system.

Materials Used in SBC Valve Guides

Manganese Bronze is a primary material for SBC valve guides due to its strength, wear resistance, and excellent heat transfer properties. Proprietary blends combining bronze with other alloys are also used for enhanced durability and performance.

Importance of Material Selection

Material selection for SBC valve guides is critical to ensure durability, heat transfer, and resistance to wear. The right materials minimize oil consumption and prevent premature wear, which can lead to engine performance issues. Durable materials like Manganese Bronze are often chosen for their strength and thermal properties, ensuring optimal valve operation. Proper material selection also enhances the valve guide’s ability to stabilize the valve stem and maintain precise alignment, which is essential for efficient combustion and reduced engine stress. Additionally, materials that offer excellent wear resistance reduce the need for frequent replacements, lowering maintenance costs. By choosing high-quality materials, engine builders can ensure long-term reliability and peak performance. This emphasis on material quality directly impacts the overall efficiency and longevity of the engine, making it a cornerstone of valve guide design and construction.

Common Materials for SBC Valve Guides

Common materials for SBC valve guides include Manganese Bronze, which is widely recognized for its exceptional strength, durability, and thermal conductivity. This proprietary blend is often used by manufacturers like GSC Power-Division due to its ability to withstand high engine temperatures and wear. Other materials include hardened steel and cast iron, which are known for their rigidity and resistance to deformation. These materials are chosen for their ability to maintain precise valve alignment and minimize wear over time. The choice of material depends on the engine’s application, with performance engines often opting for premium alloys that offer superior heat transfer and longevity. Proper material selection ensures the valve guide can handle the stresses of engine operation while maintaining optimal performance. The use of high-quality materials directly impacts the engine’s efficiency, making them a critical component in valve guide construction.

Proprietary Materials and Their Benefits

Proprietary materials for SBC valve guides are engineered to deliver enhanced performance and durability. These specialized blends, such as the Manganese Bronze alloy used by GSC Power-Division, are designed to provide superior strength, thermal conductivity, and wear resistance. Manufactured on dedicated CNC turning centers, these materials ensure precision and consistency. The unique composition of proprietary materials allows them to withstand the high stresses and temperatures of engine operation better than standard materials. They also offer improved lubricity, reducing friction and extending the lifespan of the valve train. Additionally, proprietary materials are often optimized for specific engine applications, such as high-performance or racing environments, where reliability and efficiency are critical. By leveraging advanced metallurgy, these materials minimize wear on the valve stem and guide, ensuring tighter clearances and better valve sealing. This results in improved engine efficiency, reduced oil consumption, and overall enhanced performance.

Installation and Fitment of SBC Valve Guides

Installing SBC valve guides involves replacing the original cast-in guides by drilling them out and fitting removable ones. Proper alignment and sizing, such as using .003 or .015 stem valves, ensure precise fitment. Specialized tools are required for accurate installation, ensuring optimal performance and longevity.

Step-by-Step Installation Guide

Installing SBC valve guides requires precision and care to ensure proper fitment and functionality. Begin by preparing the engine head, ensuring it is clean and free of debris. Next, drill out the original cast-in guides using a pilot drill to maintain accuracy. Following this, ream the guide bore to the desired diameter using a valve guide reamer. Once the bore is properly sized, install the new removable valve guides, ensuring they are seated correctly and aligned with the valve seat. Use a guide driver to tap the guides into place gently. After installation, check the guide-to-stem clearance using a dial indicator to ensure proper alignment. Finally, test the valves for smooth operation and proper sealing. This process ensures optimal performance and longevity of the engine. Specialized tools, such as reamers and guide drivers, are essential for a successful installation.

Tools and Equipment Required

Installing SBC valve guides demands specific tools to ensure accuracy and proper fitment. A valve guide reamer is essential for sizing the guide bore to the correct diameter, while a pilot drill helps maintain precision during the drilling process. A guide driver is necessary for tapping the new guides into place without causing damage. Additionally, a dial indicator is used to measure guide-to-stem clearance, ensuring proper alignment. Other tools include a drill press for controlled drilling, a set of precision measuring instruments, and a cleaning kit to remove debris from the head. Specialized tools like guide installers and reamers are often available in aftermarket kits, which may also include spare guides and sizing components. Using high-quality, durable tools made from materials like Manganese Bronze ensures longevity and precision. Proper equipment is crucial for a successful installation, as it directly impacts the performance and longevity of the engine. Always refer to manufacturer specifications for tool recommendations.

Common Mistakes to Avoid During Installation

During the installation of SBC valve guides, several common mistakes can lead to poor performance or engine damage. One of the most frequent errors is improper reaming of the guide bore, which can result in uneven surfaces or incorrect sizing. Using the wrong size guide or failing to align it properly can cause misalignment and increased wear. Another mistake is not using a pilot drill before reaming, which can lead to crooked or oversized bores. Over-tightening the guide during installation can damage the head or the guide itself. Additionally, insufficient cleaning of the head and guide area can leave debris, affecting the seal and causing oil leakage. Neglecting to measure guide-to-stem clearance can result in improper valve operation. Lastly, rushing the process without following manufacturer specifications often leads to subpar results. Avoiding these mistakes ensures a precise, durable installation that maintains engine efficiency and longevity.

Maintenance and Inspection of SBC Valve Guides

Regular inspection of SBC valve guides is crucial for identifying wear and tear. Cleaning the guides and surrounding areas ensures proper lubrication and prevents debris buildup. Inspecting for excessive clearance or damage helps maintain optimal engine performance and longevity.

Regular Inspection Techniques

Regular inspection of SBC valve guides is essential to ensure optimal engine performance and prevent potential issues. Start by visually examining the guides for signs of wear, such as excessive clearance or scoring. Use precision measuring tools to check the guide-to-stem clearance, as improper alignment can lead to oil consumption and reduced efficiency. Inspect the valve stem for straightness and ensure it moves smoothly within the guide. Additionally, check for heat damage or discoloration, which may indicate improper cooling or excessive friction. Clean the area around the guides to remove dirt and debris, which can interfere with proper inspection. If any damage or wear is detected, consider replacing the guides to maintain engine longevity. Regular inspections help identify problems early, preventing costly repairs and ensuring the valve train operates smoothly.

Cleaning and Lubrication Practices

Cleaning and lubrication are crucial for maintaining the functionality of SBC valve guides. Start by removing dirt and debris using a solvent and a soft-bristle brush to avoid damaging the guides; Once clean, apply a thin layer of engine oil or a high-temperature grease to the valve stem and guide interface. This reduces friction and prevents wear during engine operation. Regular lubrication ensures smooth movement of the valve stem within the guide, which is essential for proper engine performance. Avoid using excessive lubricant, as it can attract dirt and cause premature wear. For optimal results, use lubricants specifically designed for high-temperature applications, as they provide better durability under extreme conditions. Proper cleaning and lubrication practices help extend the lifespan of SBC valve guides and maintain engine efficiency.

Performance Impact of SBC Valve Guides

SBC valve guides significantly impact engine performance by ensuring proper valve alignment and reducing oil consumption. They enhance efficiency, stabilize the valve train, and prevent excessive wear, contributing to overall engine reliability and longevity.

Role in Engine Efficiency

SBC valve guides play a crucial role in maintaining engine efficiency by ensuring proper valve alignment and reducing wear. They support the valve stem, preventing misalignment that could lead to inefficient combustion and reduced power output. By guiding the valve accurately, they minimize lateral movement, which can cause excessive wear on other components. Additionally, SBC valve guides help in transferring heat from the valve to the cylinder head, preventing overheating and potential engine damage. Properly functioning valve guides also reduce oil consumption by preventing oil from entering the combustion chamber, which can lower fuel efficiency and increase emissions. High-quality SBC valve guides, such as those made from proprietary materials like Manganese Bronze, offer superior durability and precision, further enhancing engine performance. Overall, they are essential for maintaining optimal engine efficiency, reliability, and longevity.

Impact on Valve Train Stability

SBC valve guides significantly influence valve train stability by ensuring precise alignment and minimizing lateral movement of the valve stem. Properly functioning guides prevent excessive wear on the valve train components, such as the rocker arms and lifters, which can lead to instability and poor engine performance. When valve guides are worn, they allow the valve stem to move excessively, causing misalignment and inconsistent valve timing. This instability can result in reduced power output, poor engine idle, and increased wear on other critical components. High-quality SBC valve guides, made from durable materials like Manganese Bronze, provide superior stability by maintaining tight tolerances and reducing valve stem wobble. This ensures consistent valve operation, which is essential for maintaining optimal engine performance and longevity. By stabilizing the valve train, SBC valve guides play a critical role in delivering reliable engine operation under various driving conditions.

Troubleshooting Common Issues

Common issues with SBC valve guides include excessive oil consumption, increased valve stem movement, and poor engine performance. Worn guides often cause these problems, requiring inspection and replacement to restore proper valve alignment and engine efficiency.

Signs of Worn-Out Valve Guides

Worn-out SBC valve guides often exhibit specific symptoms that indicate the need for inspection or replacement. One of the most common signs is increased oil consumption, as worn guides allow excess oil to enter the combustion chamber. Additionally, misalignment of the valve stem within the guide can lead to poor engine performance, including decreased power and rough idling. Another noticeable sign is excessive valve train noise, such as clattering or tapping sounds, which result from improper valve stem alignment. Over time, worn guides can also cause the valves to move out of their intended position, leading to improper sealing and potential engine damage. Regular inspection is crucial to identify these issues early, as neglected worn guides can escalate into more severe problems, including valve failure and increased maintenance costs. Addressing these signs promptly ensures optimal engine efficiency and longevity.

Diagnosing Oil Consumption Issues

Diagnosing oil consumption issues in SBC valve guides involves identifying excessive oil burning, which is often indicated by blue smoke from the exhaust. This occurs when worn guides allow engine oil to enter the combustion chamber. A leak-down test can help pinpoint the source of the issue by pressurizing the cylinder and checking for leaks. Additionally, a visual inspection using a bore scope can reveal wear patterns or damage to the valve guides. Excessive clearance between the valve stem and guide is a common cause, leading to oil seepage. Addressing these issues promptly is crucial, as prolonged oil consumption can result in premature wear on engine components, including pistons and cylinders. Regular maintenance and inspection of the valve guides are essential to prevent such problems and ensure optimal engine performance. Early detection and repair can significantly extend the lifespan of the engine and maintain its efficiency.

SBC valve guides are essential for engine performance, supporting valves and ensuring proper alignment. They play a key role in heat transfer and reducing oil consumption. Regular maintenance and inspection are crucial for their longevity and optimal engine function.

SBC valve guides are essential for maintaining engine performance and longevity. They support the valve stem, ensure proper alignment, and facilitate heat transfer, which is critical for engine efficiency. Proper material selection, such as manganese bronze or proprietary blends, ensures durability and optimal performance. Installation requires precision to avoid common mistakes like misalignment or improper fitting. Regular inspection and maintenance, including cleaning and lubrication, are vital to prevent wear and tear. Worn-out guides can lead to increased oil consumption and reduced engine stability. Addressing issues early and using high-quality materials can enhance valve train stability and overall engine efficiency. By understanding the role and importance of SBC valve guides, engine builders and enthusiasts can make informed decisions to optimize their engine’s performance and lifespan.

Future Trends in SBC Valve Guide Technology

Future trends in SBC valve guide technology are expected to focus on advanced materials and precision manufacturing. Proprietary blends, such as manganese bronze, are likely to evolve further, offering improved durability and heat resistance. Additionally, advancements in CNC machining will enable tighter tolerances and more consistent performance. There may also be a shift toward lightweight, high-strength materials to reduce weight while maintaining strength. Innovations in surface coatings could enhance wear resistance and thermal conductivity, further improving engine efficiency. As engine designs become more sophisticated, valve guides may incorporate integrated cooling features or optimized geometries to better manage heat and stress. These advancements will aim to address the increasing demands of high-performance engines while ensuring reliability and longevity. By leveraging cutting-edge technology, future SBC valve guides will play a critical role in enhancing overall engine performance and efficiency.